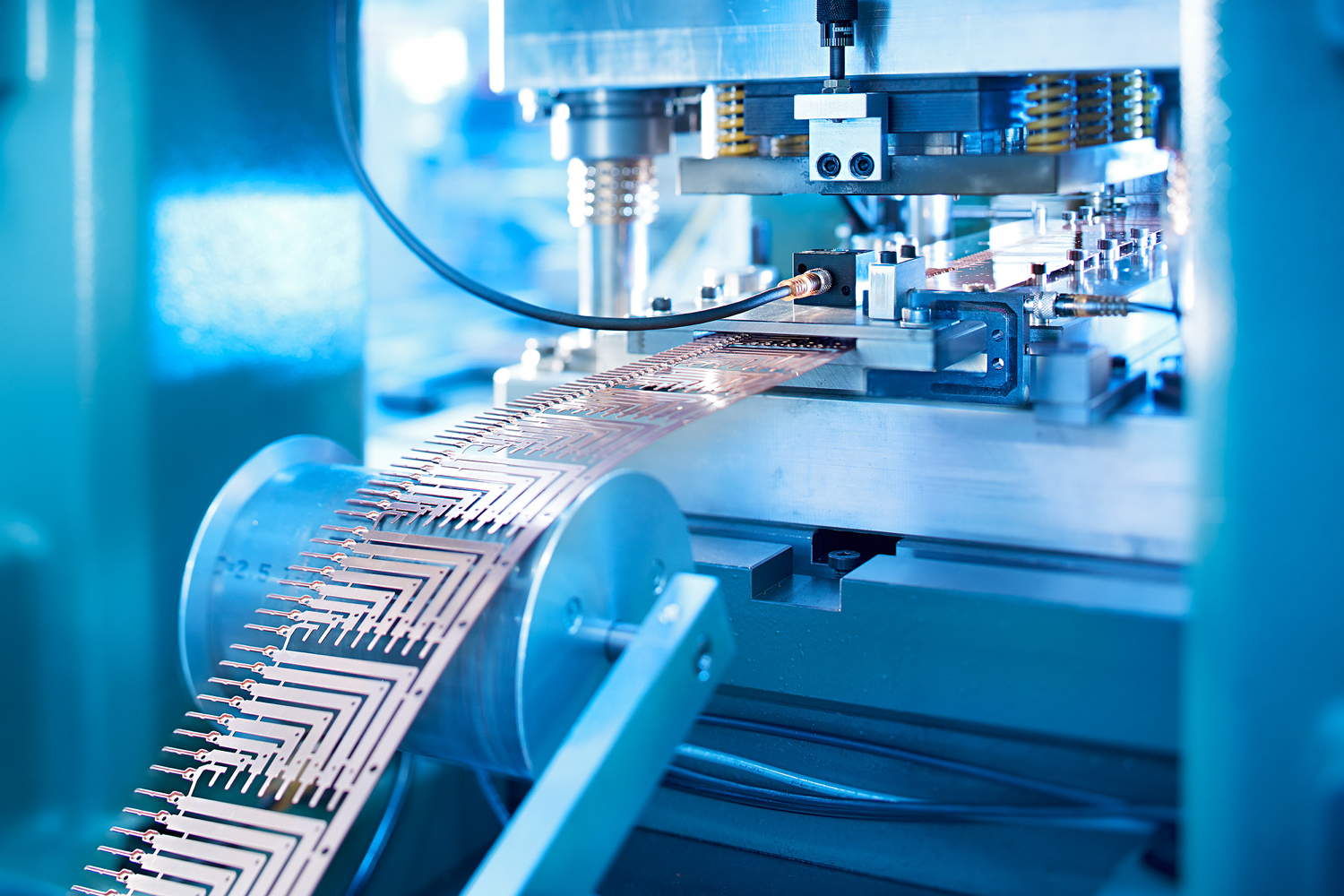

CUSTOMER BENEFITS

-

EJECTION

Function monitoring of ejection controlling -

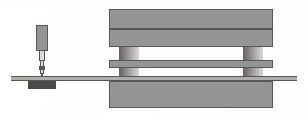

FEEDER

Monitoring and ensuring correct strip feeders -

STRIP END

Timely detection of strip ends -

DOUBLE SHEETS

Detection of double sheets -

STAMPING WASTE

Detection of stamping waste -

SCRAP

Detection of scrap -

PUNCHING BREAKAGE

Detection of punching breakage -

MODULE PROTECTION

Monitoring of module-fixing screws -

BENDING AND SHAPING

Force measuring punching -

STRIP END

Measuring and monitoring strip thickness

Products

-

SPP610

Compact monitoring system with digital and analog inputs. -

SPP620

Compact control and monitoring system with digital inputs and outputs. -

SPP630

Modular control and monitoring system with analog inputs and digital inputs and outputs. -

SPP800

Modular, high-performance system for monitoring and controlling all processes on the press and tool. -

SENSORS

Optical and inductive sensors, particularly developed for the stamping sector