|

Tool monitoring and control system for presses

The SPP 800 impresses with its innovative, modular design and optimally protects your investment for the future.�

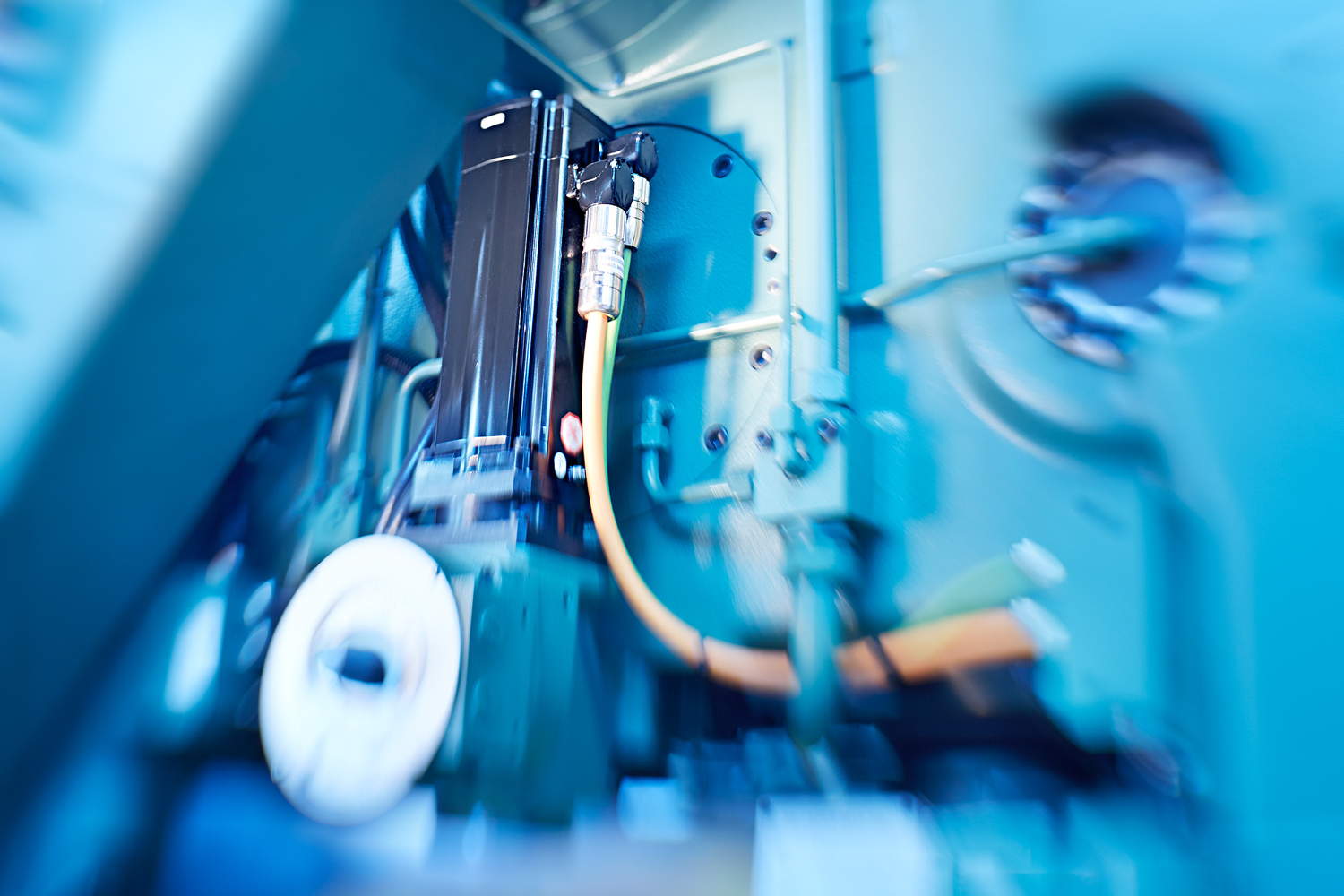

Intelligent, flexible operation monitoring and control functions ensure safe and efficient production. The modular hardware for connecting the peripherals is in a separate control cabinet.�

The connection to the service unit is via an EtherCAT Bus system, making the system practically upgradable in any way.

Feeder and parts ejection errors are detected by tool protection with digital sensors. by utilising acoustic emission and force sensors, punching breakage and stamping scrap can be identified and bending and shaping operations can be monitored reliably.

Functions and peripherals, such as sorting, stamp stacking and other applications can be controlled by the outputs.

The integration of a Siegfried oiling system upgrades the SPP 800 to a central monitoring and control unit for your machine.

|